Samara Instruments’ state-of-the-art lab solutions help you to accomplish extraordinary precision and effectiveness, which leads to quicker outcomes, minimised errors and increased output.

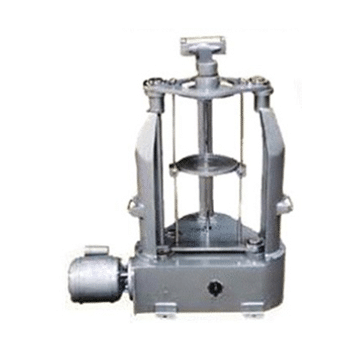

We manufactured this phenomenal product, called RoTap Sieve Shaker, to offer you high-performance, which facilitates the efficiency of particle size examination and grading processes. No matter what industry you are in, whether it is drug manufacturing, chemical manufacturing , mineral extraction , building and construction or food and beverage manufacturing, this instrument constantly delivers precise and trustable outcomes that meet your quality expectations.

Where Precision Drives Performance

When you choose to invest in the RoTap Sieve Shaker, you are not just investing in a device but in precision based performance and the future success of your laboratory.

It is a perfect blend of a powerful motor driven platform and a precisely controlled tapping mechanism, which provides efficient particle size classification, leading to better quality of the product and decreased wastage.

This versatile shaker is designed for both research and industrial facilities, its adaptability streamlines your testing procedures with utmost accuracy, ensuring optimal results.

Main Features and Advantages

Abrasion Proof: Manufactured with high quality materials to withstand rigorous usage in the laboratory.

Strong and Resilient: Guarantees constant and trustable operation while keeping the wear and tear negligible during continuous usability.

Corrosion Resistance: Provides better durability while keeping the components safeguarded against rust.

High Tech Tapping Systems: Utilizes both tapping and shaking functions to accomplish optimal separation.

Timer and Speed Controller: Adjust the speed and time tapping and shaking according to specific materials and testing demands.

Dust Protected Operation: Protects your setup from contamination and keeps it hygienic and clean.

User Friendly and Space Efficient Design: Decreases setup and operational complexity, thereby freeing up valuable space in the laboratory

How It Functions

The RoTap Sieve Shaker utilizes a dynamic process which involves vigorous shaking and vertical tapping of the sieves for effective separation of materials. The shaker holds a stack of sieves, organized from smallest to biggest mesh, is firmly attached to the shaker. As the device operates, particles are effectively separated based on size through the corresponding sieve apertures, enabling accurate characterisation of the particle size distribution.

A Multi-Industry Solution

This highly flexible equipment is manufactured for a variety of applications, which makes it a crucial tool across many different industries:

Pharmaceutical Production: Guarantees accuracy in particle sizings for drug formulations

Fine Chemical Manufacturing: Maintains consistent quality and output in fine chemical production

Mining Operations: Supports accurate evaluation of aggregate and mineral characteristics

Food Manufacturing: Offers a means for accurate grading and classification of granular food materials in accordance to their size and quality.

Crafted for Technical Elites like You

We know that laboratory analysts and technicians demand superior, dependable and high power devices. The RoTap Sieve Shaker offers:

User-friendly interface: Effortless Sieve Setup and convenient operation.

Massive Productivity: Conduct various tests effectively in lesser durations.

Fulfills industrial Standards: Offers precise and trustable performance in adherence with industry norms.

Why Should Samara Instruments be Your Number One Choice?

You are putting your money into more than just a piece of equipment when you choose our RoTap Sieve Shaker.

This phenomenal product will be your trusted laboratory partner which is fully dedicated to assist you in achieving massive success.

With features loaded with high scale technology like digital controls and timers, superior endurability, advanced safety features etc we make sure that your laboratory functions at the top level. Our after-sales support team is also always there for you to resolve your queries related to the product.

Don’t Wait, Choose Smart Today

Elevate your laboratory’s abilities with the RoTap Sieve Shaker. No matter you are doing regular quality checks or high level research, this equipment is your most effective solution for trustable particle size examination.

Call Samara Instruments now to learn more and invite accuracy and effectiveness to your laboratory procedures. Let’s be a team and work together in enhancing your workforce to the another level.

Features

Specifications

| Model No | SI - RTS/114 | |||

|---|---|---|---|---|

| Heavy duty, for 8 ”, 12 ” & 18” test sieves | ||||

| Durably constructed | ||||

| No foundations are required | ||||

| ¼ H.P. Electric motor 220 Volts.C through reduction gear | ||||

| Equipped to carry upto 6/7 TEST SIEVES of 200 mm Dia (8") with one set lid & pan | ||||

| Reproduces circular and hammering motion | ||||

| Circular (revolution approx. : 280 to 320 R.P.M and tapping approx.: 140 R.P.M to 160 R.P.M) | ||||

| Timer | With Timer | Without Timer | ||

Samara Instruments’ state-of-the-art lab solutions help you to accomplish extraordinary precision and effectiveness, which leads to quicker outcomes, minimised errors and increased output.

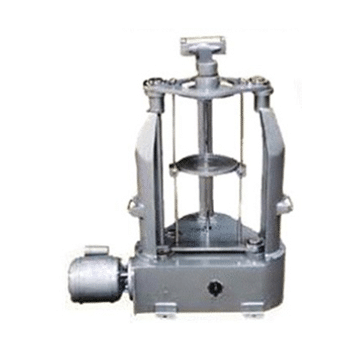

We manufactured this phenomenal product, called RoTap Sieve Shaker, to offer you high-performance, which facilitates the efficiency of particle size examination and grading processes. No matter what industry you are in, whether it is drug manufacturing, chemical manufacturing , mineral extraction , building and construction or food and beverage manufacturing, this instrument constantly delivers precise and trustable outcomes that meet your quality expectations.

Where Precision Drives Performance

When you choose to invest in the RoTap Sieve Shaker, you are not just investing in a device but in precision based performance and the future success of your laboratory.

It is a perfect blend of a powerful motor driven platform and a precisely controlled tapping mechanism, which provides efficient particle size classification, leading to better quality of the product and decreased wastage.

This versatile shaker is designed for both research and industrial facilities, its adaptability streamlines your testing procedures with utmost accuracy, ensuring optimal results.

Main Features and Advantages

Abrasion Proof: Manufactured with high quality materials to withstand rigorous usage in the laboratory.

Strong and Resilient: Guarantees constant and trustable operation while keeping the wear and tear negligible during continuous usability.

Corrosion Resistance: Provides better durability while keeping the components safeguarded against rust.

High Tech Tapping Systems: Utilizes both tapping and shaking functions to accomplish optimal separation.

Timer and Speed Controller: Adjust the speed and time tapping and shaking according to specific materials and testing demands.

Dust Protected Operation: Protects your setup from contamination and keeps it hygienic and clean.

User Friendly and Space Efficient Design: Decreases setup and operational complexity, thereby freeing up valuable space in the laboratory

How It Functions

The RoTap Sieve Shaker utilizes a dynamic process which involves vigorous shaking and vertical tapping of the sieves for effective separation of materials. The shaker holds a stack of sieves, organized from smallest to biggest mesh, is firmly attached to the shaker. As the device operates, particles are effectively separated based on size through the corresponding sieve apertures, enabling accurate characterisation of the particle size distribution.

A Multi-Industry Solution

This highly flexible equipment is manufactured for a variety of applications, which makes it a crucial tool across many different industries:

Pharmaceutical Production: Guarantees accuracy in particle sizings for drug formulations

Fine Chemical Manufacturing: Maintains consistent quality and output in fine chemical production

Mining Operations: Supports accurate evaluation of aggregate and mineral characteristics

Food Manufacturing: Offers a means for accurate grading and classification of granular food materials in accordance to their size and quality.

Crafted for Technical Elites like You

We know that laboratory analysts and technicians demand superior, dependable and high power devices. The RoTap Sieve Shaker offers:

User-friendly interface: Effortless Sieve Setup and convenient operation.

Massive Productivity: Conduct various tests effectively in lesser durations.

Fulfills industrial Standards: Offers precise and trustable performance in adherence with industry norms.

Why Should Samara Instruments be Your Number One Choice?

You are putting your money into more than just a piece of equipment when you choose our RoTap Sieve Shaker.

This phenomenal product will be your trusted laboratory partner which is fully dedicated to assist you in achieving massive success.

With features loaded with high scale technology like digital controls and timers, superior endurability, advanced safety features etc we make sure that your laboratory functions at the top level. Our after-sales support team is also always there for you to resolve your queries related to the product.

Don’t Wait, Choose Smart Today

Elevate your laboratory’s abilities with the RoTap Sieve Shaker. No matter you are doing regular quality checks or high level research, this equipment is your most effective solution for trustable particle size examination.

Call Samara Instruments now to learn more and invite accuracy and effectiveness to your laboratory procedures. Let’s be a team and work together in enhancing your workforce to the another level.

Features:

Specifications

| Model No | SI - RTS/114 | |||

|---|---|---|---|---|

| Heavy duty, for 8 ”, 12 ” & 18” test sieves | ||||

| Durably constructed | ||||

| No foundations are required | ||||

| ¼ H.P. Electric motor 220 Volts.C through reduction gear | ||||

| Equipped to carry upto 6/7 TEST SIEVES of 200 mm Dia (8") with one set lid & pan | ||||

| Reproduces circular and hammering motion | ||||

| Circular (revolution approx. : 280 to 320 R.P.M and tapping approx.: 140 R.P.M to 160 R.P.M) | ||||

| Timer | With Timer | Without Timer | ||

Samara Instruments is a trusted source for cutting-edge scientific equipment. We specialize in providing high-quality instruments and solutions for researchers, laboratories, and scientific professionals worldwide. With 8 years of industry experience, we are committed to delivering innovative products that empower scientific discovery and advancement.

Samara Instruments’ state-of-the-art lab solutions help you to accomplish extraordinary precision and effectiveness, which leads to quicker outcomes, minimised errors and increased output.

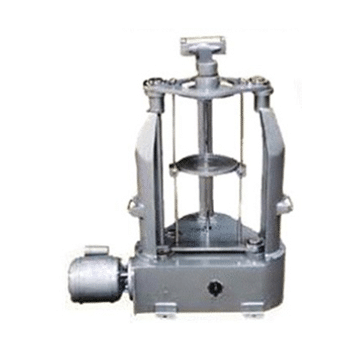

We manufactured this phenomenal product, called RoTap Sieve Shaker, to offer you high-performance, which facilitates the efficiency of particle size examination and grading processes. No matter what industry you are in, whether it is drug manufacturing, chemical manufacturing , mineral extraction , building and construction or food and beverage manufacturing, this instrument constantly delivers precise and trustable outcomes that meet your quality expectations.

Where Precision Drives Performance

When you choose to invest in the RoTap Sieve Shaker, you are not just investing in a device but in precision based performance and the future success of your laboratory.

It is a perfect blend of a powerful motor driven platform and a precisely controlled tapping mechanism, which provides efficient particle size classification, leading to better quality of the product and decreased wastage.

This versatile shaker is designed for both research and industrial facilities, its adaptability streamlines your testing procedures with utmost accuracy, ensuring optimal results.

Main Features and Advantages

Abrasion Proof: Manufactured with high quality materials to withstand rigorous usage in the laboratory.

Strong and Resilient: Guarantees constant and trustable operation while keeping the wear and tear negligible during continuous usability.

Corrosion Resistance: Provides better durability while keeping the components safeguarded against rust.

High Tech Tapping Systems: Utilizes both tapping and shaking functions to accomplish optimal separation.

Timer and Speed Controller: Adjust the speed and time tapping and shaking according to specific materials and testing demands.

Dust Protected Operation: Protects your setup from contamination and keeps it hygienic and clean.

User Friendly and Space Efficient Design: Decreases setup and operational complexity, thereby freeing up valuable space in the laboratory

How It Functions

The RoTap Sieve Shaker utilizes a dynamic process which involves vigorous shaking and vertical tapping of the sieves for effective separation of materials. The shaker holds a stack of sieves, organized from smallest to biggest mesh, is firmly attached to the shaker. As the device operates, particles are effectively separated based on size through the corresponding sieve apertures, enabling accurate characterisation of the particle size distribution.

A Multi-Industry Solution

This highly flexible equipment is manufactured for a variety of applications, which makes it a crucial tool across many different industries:

Pharmaceutical Production: Guarantees accuracy in particle sizings for drug formulations

Fine Chemical Manufacturing: Maintains consistent quality and output in fine chemical production

Mining Operations: Supports accurate evaluation of aggregate and mineral characteristics

Food Manufacturing: Offers a means for accurate grading and classification of granular food materials in accordance to their size and quality.

Crafted for Technical Elites like You

We know that laboratory analysts and technicians demand superior, dependable and high power devices. The RoTap Sieve Shaker offers:

User-friendly interface: Effortless Sieve Setup and convenient operation.

Massive Productivity: Conduct various tests effectively in lesser durations.

Fulfills industrial Standards: Offers precise and trustable performance in adherence with industry norms.

Why Should Samara Instruments be Your Number One Choice?

You are putting your money into more than just a piece of equipment when you choose our RoTap Sieve Shaker.

This phenomenal product will be your trusted laboratory partner which is fully dedicated to assist you in achieving massive success.

With features loaded with high scale technology like digital controls and timers, superior endurability, advanced safety features etc we make sure that your laboratory functions at the top level. Our after-sales support team is also always there for you to resolve your queries related to the product.

Don't Wait, Choose Smart Today

Elevate your laboratory’s abilities with the RoTap Sieve Shaker. No matter you are doing regular quality checks or high level research, this equipment is your most effective solution for trustable particle size examination.

Call Samara Instruments now to learn more and invite accuracy and effectiveness to your laboratory procedures. Let's be a team and work together in enhancing your workforce to the another level.

| Model No | SI - RTS/114 | |||

|---|---|---|---|---|

| Heavy duty, for 8 ”, 12 ” & 18” test sieves | ||||

| Durably constructed | ||||

| No foundations are required | ||||

| ¼ H.P. Electric motor 220 Volts.C through reduction gear | ||||

| Equipped to carry upto 6/7 TEST SIEVES of 200 mm Dia (8") with one set lid & pan | ||||

| Reproduces circular and hammering motion | ||||

| Circular (revolution approx. : 280 to 320 R.P.M and tapping approx.: 140 R.P.M to 160 R.P.M) | ||||

| Timer | With Timer | Without Timer | ||